Rupture discs, or blow plugs, are simple devices intended to relieve overpressure within an extruder barrel, preventing pressure related incidents which could cause damage to machinery or injury to personnel. However, if an incident does occur, your blow plug provider should be able to provide you with the testing procedure used during manufacture of the units, a certification of the testing results, and traceability of the materials used in the case of any machine warranty or legal action.

Proper blow plug design starts with industry accepted materials, typically 303 or 304 stainless steel for the body and a nickel 600 alloy for the disk itself. The inside diameter of the blow plug body should be large enough to allow for adequate evacuation of material. A small, <3/16” inside diameter is a warning sign of an improperly designed blow plug.

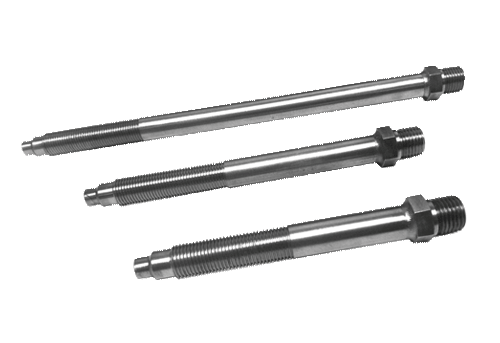

After manufacture, the blow plugs are tested to ASME specifications which require the production of additional units in the batch for testing. Those additional units are blown at room temperature and temperature derating curves are used to establish the rating at an elevated temperature that is typical in polymer extrusion. A batch or job number is established and stamped, if possible, on the body of the unit. A batch or job file under the same number is then populated with the test data and material certifications and then is kept indefinitely. By referencing the batch or job number, that information can be retrieved for whatever purpose it is needed. See this example of a proper burst and material certification sheet and see pictured below an image of a blow plug with the job number.

Country of origin of the blow plugs is also an important factor. Blow plugs made in countries with weak or inaccessible legal systems eliminate any legal recourse in the event of an improperly made unit that results in machine damage or personnel injury. It is essential with pressure relief products, since they are safety products, to ensure that they have been properly designed, tested, and certified and that there is traceability to those certifications in the case of a pressure related incident which results in damage to machinery or injury to personnel.

Extrusion Control & Supply’s blow plugs are designed for the polymer extrusion process, tested to ASME specifications with certification and traceability to the original testing and all of the materials and are made in the USA.

Call our expert team today at 770-784-7515 or email sales@extrusioncontrol.com for a comprehensive discussion about your blow plug needs.

Check us out on YouTube for more information on specifying our extruder screens and screen packs: https://www.youtube.com/watch?v=5f5p5V6lrYc .