When performing a filter pressure test (FPT), the differential pressure increase is dependent on the retention characteristics of the filter media. In order to get accurate, comparable results it is important that the filter media is assembled exactly to specification. Any change in specification, such as weaving pattern, surface condition, and especially the number of apertures per unit length and the wire diameters of the individual layers, can lead to a different test result.

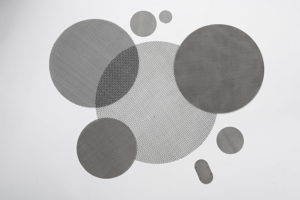

ECS screen-packs are assembled from ultrasonically cleaned filter discs, with precise wire diameters in a multi-layer construction, bound together in an aluminum frame. All screens shall be made from materials (e.g. stainless steel, monel, etc.) appropriate to the polymer used. You can be confident that every screen meets the ISO 23900-5:2015 standards as specified for 6.6.4 Screen-pack 3 (below).

6.6.2 Screen-pack 1

Two-layer construction, where the first layer is a reverse plain dutch weave 615/108 warp/weft per 25,4 mm with a wire diameter of 0,042 mm/0,14 mm and the second layer (support mesh) is a square mesh plain weave 0,63 mm aperture width with a wire diameter of 0,40 mm calendered (for further details see ISO 9044).

6.6.3 Screen-pack 2

Two-layer construction, where the first layer is a reverse plain dutch weave 615/132 warp/weft per 25,4 mm with a wire diameter of 0,042 mm/0,13 mm and the second layer (support mesh) is a square mesh plain weave 0,63 mm aperture width with a wire diameter of 0,40 mm calendered (for further details see ISO 9044).

6.6.4 Screen-pack 3

Three-layer construction, where the first layer is a twilled dutch weave 165/1400 warp/weft per 25,4 mm with a wire diameter of 0,071 mm/0,040 mm and the second layer (support mesh) is a square mesh plain weave 0,25 mm aperture width with a wire diameter of 0,16 mm and the third layer (support mesh) is

a square mesh plain weave 0,63 mm aperture width with a wire diameter of 0,40 mm calendered (for further details see ISO 9044).

Call our expert team today at 770-784-7515 or email sales@extrusioncontrol.com to discuss your needs, and check out our YouTube video for more information on Specifying Extruder Screens and Screen Packs.